1500mpa·S Edgebanding Hot Melt Adhesive Chip Board Woodworking EVA-JF-202

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | WANLI-ADHESION |

| Certification: | ISO9001 ISO14001 IATF16949 |

| Model Number: | EVA-JF-202 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 25 KG |

|---|---|

| Packaging Details: | 25Kg/Bag |

| Delivery Time: | 5-8 work days |

| Payment Terms: | L/C, T/T |

|

Detail Information |

|||

| Product: | EVA Hot Melt Adhesive | Component: | EVA (Ethylene-Vinyl Acetate) |

|---|---|---|---|

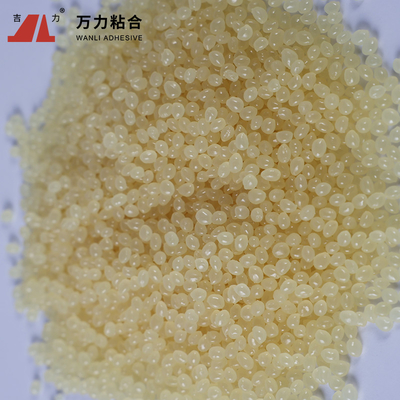

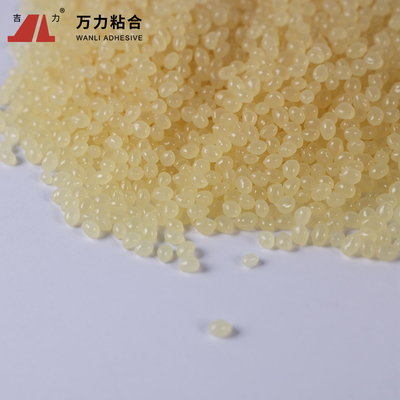

| Appearance: | Round / Yellow Particles | Solid Content: | 100 Percent |

| Shelf Life: | 2*Years | Melt Viscosity: | 11500±1500mpa·s (180℃) |

| Softening Temperature: | 88℃~98℃ | Operating Temperature: | 170 ℃~190 ℃ |

| Usage Scope: | 3D Lamination And Edgebanding For Chip Board | Application Industry: | Woodworking - Edgebanding |

| Highlight: | yellow particles edgebanding Hot Melt Adhesive,1500 mpa·s Edgebanding Hot Melt Adhesive,3D edgebanding Hot Melt Adhesive |

||

Product Description

Factory Directly Supply EVA Hot Melt Adhesive WANLI® EVA-JF-202 with Viscosity 11500±1500mpa·s (180℃) for Chip Board Edge Bonding

Wanli® EVA hot melt adhesive JF-202 for 3D lamination & edgebanding is a ethylene-vinyl acetate copolymer with 100% solid content. It is specifically developed for 3D lamination bonding of chip board to various kinds of decorative paper and edgebanding bonding of chip board to various kind of edge band. It is featured fast curing, high bonding strength and lower cost.

APPLICATION

Wanli® EVA hot melt adhesive JF-202 is used for 3D lamination bonding of chip board to various kinds of decorative paper and edgebanding bonding of chip board to various kind of edge band.

| Application Material | Woodworking 3D Lamination & Edgebanding Hot Melt Adhesives |

| Appearance | Round yellow particles |

| Component | EVA |

| Application Industry | Woodworking Edgebanding |

| Solid Content | 100% |

| Operating Temperature | 170℃~190 ℃( Depend On Machine, Substrate, Environment And Other Conditions). |

| Softening Temperature | 88℃~98 ℃ |

| Melt Viscosity | 11500±1500mpa·s (180℃) |

| Curing | Normal Temperature Curing |

| Usage Scope | 3D lamination and edgebanding |

| Shelf Life | 2 Years |

| Package | 25Kg/Bag |

FEATURE

Fast curing, high bonding strength and lower cost

USER GUIDE

The package of JF-202 is suitable for various dispensing equipment. Especially for high-speed automatic 3D lamination machines. Recommended tank temperature is 170℃~190℃. Recommended sizing temperature is 170℃~190℃. Recommended dosage is 40g~80g/㎡.

STORAGE

Storage humidity less than 70% RH, temperature should be 5℃~25℃, please pay attention to avoid direct sunlight, FIFO.

![]()

![]()

![]()