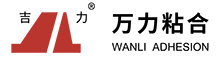

Aluminum PUR Hot Melt Adhesives Edge Bonding Chip Particle Density Foam PUR-7563A

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | WANLI-ADHESION |

| Certification: | ISO9001 ISO14001 IATF16949 |

| Model Number: | PUR-7563A |

Payment & Shipping Terms:

| Minimum Order Quantity: | 20 KG |

|---|---|

| Packaging Details: | 500~2000g/Bag, 20Kg/Barrel, 200Kg/Barrel |

| Delivery Time: | 5-8 work days |

| Payment Terms: | L/C, T/T |

|

Detail Information |

|||

| Product: | PUR Hot Melt Adhesive | Component: | PUR (Polyurethane) |

|---|---|---|---|

| Appearance: | White Solid | Solid Content: | 100% |

| Shelf Life: | 6 Months | Melt Viscosity: | About 65000cps@120℃ |

| Operating Temperature: | 120~140 ℃ | Open Time: | About 10s@25℃ |

| Useage Scope: | Edge Bonding Of Wood Material S- Chip Board | Application Industry: | Woodworking Edgebanding |

| Highlight: | aluminum PUR Hot Melt Adhesives,edge bonding PUR Hot Melt Adhesives,chip pur hotmelt |

||

Product Description

Polyurethane hot melt glue PUR-7563A can be used for a broad spectrum of adhesion to different edgeband materials. Fast adhesive setting for direct downline processing and high heat resistance and durability. Wanli supplies these hot melt adhesives of the latest generation also in granulate form. The ease of processing makes them particularly attractive for processers who have not used the PUR technology before

Wanli® PUR hot melt adhesive PUR-7563A for edge bonding is a single-component reactive PUR hot melt adhesive with 100% solid content. PUR-7563A is a cleaning free glue, which is mainly used for edge bonding of solid wood materials, MDF, foam boards and other substrates. PUR-7563A is featured stable viscosity under heating at a certain temperature, short open time, high initial bonding strength, high final bonding strength and no cleaning.

APPLICATION

Wanli® PUR hot melt adhesive PUR-7563A is used for edge bonding. PUR-7563A is mainly used for edge bonding of solid wood materials, MDF, foam boards and other substrates.

| Application Material | Woodworking Edgebanding Hot Melt Adhesives |

| Appearance | White Solid |

| Component | PUR (Polyurethane) |

| Application Industry | Woodworking Edgebanding |

| Solid Content | 100% |

| Operating Temperature | 120~140 ℃( Depend On Machine, Substrate, Environment And Other Conditions) |

| Melt Viscosity | About 65000cps@120℃(Brookfield-ASTMD3236) |

| Open Time | About 10s@25℃ |

| Usage Scope | Edge Bonding of Wood Materials - Chip Board |

| Shelf Life | 6 Months |

| Package | 500~2000g/Bag, 20Kg/Barrel, 200Kg/Barrel |

FEATURE

Stable viscosity under heating at a certain temperature.

Short open time.

High initial bonding strength.

High final bonding strength and no cleaning.

USER GUIDE

The package of PUR-7563A is suitable for various dispensing equipment.

The recommended operating temperature is 120℃~140℃.

It is better to place finished product in a working environment with suitable temperature and humidity to achieve complete curing (recommended temperature: 23~25℃, about 65% relative humidity).

STORAGE

Dry, cool, avoid direct sunlight, no more than 35℃.

![]()

![]()